Commercial Placer Mining Equipment

.

|

Commercial Placer Mining Equipment |

|

||

|

. |

Interested in finding more about commercial scale operations to mine gold nuggets? This is my page of information on Commercial placer mining equipment. At one point or another, many prospectors wish they could scale up their operations and get a lot more gold. There are a lot of different options as far as equipment, and in the article below I'll take a look at all of the best known commercial mining systems for getting the gold and other valuable minerals out of your gravels and recovering placer gold. Take a look at the following information....... |

|

|

|

|

||

|

Commercial placer mine operators can afford the expense, and need the capability of larger equipment that is beyond the typical workings of the small operator or individual prospector - this level of financial capacity is required to mine on a commercial scale. Three of the most common pieces of commercial placer processing equipment are jigs, shaking tables, and spiral concentrators. Lets take a look at each of these types and some additional considerations as well.....

Jigs |

||

|

The conventional jig is a high capacity concentrator that efficiently separates material from I inch down to about 100 mesh (25.4 mm to 150 microns), although significant recovery of gold finer than 230 mesh (roughly 70 microns) has been reported. Jigs can process 7-25 tons of material per hour, depending on their size, with recoveries of 80- 95%. A usual configuration is a double line of four cells in series, each two cells driven by an eccentric box provided with a geared motor. These machines require a significant amount of floor space, head room, and experienced supervision. Nearly any fluctuation in feed size or rate will require the adjustment of the jig to maintain proper recovery. The actual mechanics of jigging are complex, and differing models have been developed to explain the process. Generally, the processes involved in efficient jigging are as follows. First, the compression stroke of the plunger produces an upward water pressure that causes the sand bed and feed to accelerate upward. Due to particle density, lighter particles are moved farther upwards than heavier ones. This process is called differential acceleration. Secondly, the mineral grains undergo hindered settling. After the initial acceleration, the plunger stops and the mineral grains will fall and their speeds will increase such that the grains attain terminal velocity. Since the jig bed is a loosely packed mass with interstitial water, it acts as a high density liquid that restricts the settling of lighter particles while allowing heavy particles to fall. This allows heavy grains to settle further downward than lighter material. Finally, during the suction stroke of the plunger, a period of time is allotted for the fine grains to settle on top of a bed of coarse grains. The coarse grains have settled and are wedged against each other, incapable of movement. The small grains settle through passages between the coarse particles. The process is known as consolidation trickling. |

|

|

|

In a jig, the pulsating water currents are caused by a piston having a movement with equal compression and suction strokes. At the point between pulsation and suction, the jig bed will be completely compacted, which hinders settling of all material. To keep the bed open, make-up water, referred to as hutch water or back water, is added. The addition of the hutch water creates a constant upward flow through the bed and thus increases the loss of fine material. This loss occurs partly because the longer duration of the pulsation stroke acts to carry the fine particles higher and partly because the added water increases the speed of the top flow, carrying fine particles through the jig and past the jig bed before the jigging action can settle them out.

Shaking Tables |

||

| . | ||

|

Deck sizes range from 18 by 40 inches for laboratory testing models to 7 by 15 feet. These large tables can process up to 175 tons in 24 hours. The two basic deck types are rectangular and diagonal. Rectangular decks are roughly rectangle shaped with riffles parallel to the long dimension. Diagonal decks are irregular rectangles with riffles at an angle (nearly diagonal). In both types, the shaking motion is parallel to the riffle pattern. The diagonal decks generally have a higher capacity, produce cleaner concentrates, and recover finer sized particles.

The decks are

usually constructed of wood and covered with a surface of linoleum, rubber

or plastics. These materials have a high coefficient of friction, which aids

mineral recovery. Expensive, hardwearing decks are made from fiberglass. The

riffles on these decks are formed as part of the mold. In operation, a

slurry consisting of about 25% solids by weight is fed with wash water along

the top of the table. The table is shaken longitudinally, using a slow

forward stroke and a rapid return strike that causes particles to “crawl”

along the deck parallel to the direction of motion. Wash water is fed at the

top of the table at right angles to the direction of table movement. These

forces combine to move particles diagonally across the deck from the feed

end and separate on the table according to size and density. |

|

|

|

||

|

In practice, mineral particles stratify in the protected pockets behind the riffles. The finest and heaviest particles are forced to the bottom and the coarsest and lightest particles remain at the top. These particle layers are moved across the riffles by the crowding action of new feed and the flowing film of wash water. The riffles are tapered and shorten towards the concentrate end. Due to the taper of the riffles, particles of progressively finer size and higher density are continuously brought into contact with the flowing film of water that tops the riffles, as lighter material is washed away. Final concentration takes place in the unriffled area at the end of the deck, where the layer of material at this stage is usually only a few particles deep. The separation process is affected by a number of factors. Particle size is especially important, but particle shape is important as well. Generally, as the range of sizes in feed increases, the efficiency of separation decreases. A well classified feed is essential to efficient recovery. Separation is also affected by the length and frequency of the stroke of the deck drive, usually set to 1 inch or more with an adjustable frequency that varies between about 240 to 325 strokes per minute. A fine feed requires a higher speed and shorter stroke than a coarse feed. The shaking table slopes in two directions, across the riffles from the feed to the tailings discharge end and along the line of motion parallel to the riffles from the feed end to the concentrate end. The latter greatly improves separation due to the ability of heavy particles to “climb” a moderate slope in response to the shaking motion of the deck. The elevation difference parallel to the riffles should never be less than the taper of the riffles; otherwise wash water tends to flow along the riffles rather than across them. I have a page on How to Build Your Own Shaker Table |

|

|

|

Spiral Concentrators The newer Humphreys spirals are capable of recovering particles as small as 270 mesh (53 microns). In a test at CSMRI, a new Mark VII Reichert spiral recovered 91.3% of the free gold contained in the feed in a concentrate representing only 5.4% of the feed weight. The unit showed little decrease in gold recovery efficiency with material down to 325 mesh (45microns). |

|

|

|

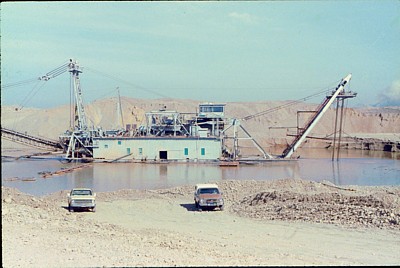

Sand and Gravel Mines |

||

Want to know a little bit more about this crazy prospector guy? Well, here's a little bit more about me, and how I got into prospecting: Chris' Prospecting Story Interested in seeing more gold? Here are some interesting photos of beautiful Gold Nuggets