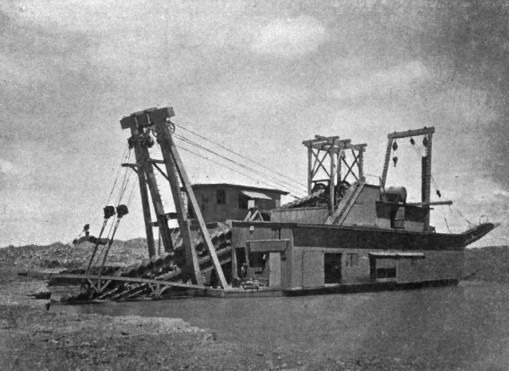

Next the miners went to mechanical mining methods. The dredges at Hammon City, as well as Oroville, Folsom and a number of other places along the western front of the Sierra were the next gold source of great magnitude. Bucket line dredging, which was started in New Zealand about 1882, and first profitably tried in the US at the Bannock district of Montana in 1893, became of great importance early in the 1900s. The modern bucket elevator dredge (often electrically driven) being capable of excavating as much as 10,000 cubic yards daily, and the buckets each having a capacity of 16 cubic feet. The total quantity of the gold produced in this manner by several states totals into the millions of ounces. A dredge is essentially a machine to excavate and recover the precious metal from gold-bearing gravel and as the transporting medium of the plant is water, a boat or scow is necessary for this purpose. Thus, a bucket line dredge consists of the hull, with its superstructure and housing; a digging ladder and continuous chain of buckets; a disintegrating and screening apparatus; a system of gold-saving devices; pumps, anchoring arrangements, and a stacker for the disposal of the coarse portion of the material excavated; and the power-plant, consisting of motors, winches, gearing, etc. The hull is built in scow form, the forward part being divided so as to form a well, in which the ladder and bucket-chain may be raised and lowered between the two halves. As the main wearing parts and, in fact, the bulk of the dredging machinery are renewed constantly on account of wear and breakage, the hull should be built to outlast the original plant, and indeed to outlast the area which it is intended to work over.

The endless bucket line dredge with stacker was practically only type of economically successful dredge that was used in the Sacramento valley. The handling of the dredger is accomplished by the use of lines and spuds, and lines. There are two spuds, i.e., long vertical members capable of being raised and lowered, and in reality forming feet for the boat, being placed at the stern of the boat. These spuds are made of steel, one being used when the other spud is raised in the process of "walking" the boat ahead. Two steel lines are provided at the forward end of the boat, which are fastened to the bank, and by means of them the boat is moved from right to left, being swung in an arc about the spuds at the stern. The gravel on being excavated and elevated is discharged into a revolving screen, within and extending its whole length is a large perforated pipe, by which means and by other jets playing on the in- and out-side of the screen, the gravel is thoroughly washed, the finer material passing through the perforations while the larger gravel and boulders are discharged at the outer and lower end of the screen, and fall overboard. In some dredgers all undersize material passes directly into a tank or sump, from which it is raised by a centrifugal pump and delivered to the sluices. In this arrangement the upper end of the sluice box rests on a turn-table, the base of which sets on the dredger. Connection is made between the pump and sluice-box by means of a short length of hose. The sluice-box is adjustable so that the tailing may be evenly distributed on the waste bank.

When tables are used on dredgers the gravel from the screens usually passes directly to them. These tables are arranged on either side of the screen, especially if it is of the revolving type, and are covered with cocoa matting alone or with cocoa matting and expanded metal. From the tables the gravel is run through sluices, placed longitudinally with the dredger, which are also provided with riffles, usually of the expanded metal forms. So-called "beehive" riffles are often used next to the screen, and consist of a nest of riffles in layers placed under the upper portion of the screen. In certain dredgers the sluices discharge into a sump from which the material is elevated and discharged overboard by a centrifugal pump, but a gravity disposal is more usual. Experience shows that most of the natural gold is saved at the upper end of the tables, in some cases even the first six inches.

These great machines employ a continuous chain of buckets for digging the gravel and taking it aboard the floating barge. Such a chain of buckets and the support for it (the ladder) may weigh 1,000 tons. The entire outfit including the digging machinery and the equipment for washing out the gold may weigh 3,750 tons. Riffle sluices and quicksilver were still used to recover the gold by amalgamation on the dredges, but on the most modern dredges, sluices were partly replaced by jigs, which are mechanical devices for concentrating the gold. The dragline type of dredge is a later development that was introduced in the 1930 's. The heavy digging equipment is an ordinary dragline excavator that travels on the bank. The floating barge carries only the screen, equipment for concentrating the gold, and the tailing-stacker." Placer gravel is handled so cheaply on these dredges that very low grade materials could be processed profitably. The greater part of the Western states are well adapted to dredging owing to a plentiful water supply, and although many of the gravel deposits have been worked over by the earlier miners operating with rockers, ground-sluices and hydraulic mining, yet either owing to hasty and inefficient work done or to the replenishing of previously exhausted ground, it is now found possible to rework them profitably by dredging. Other deposits not worked by the pioneers, owing to the light grades and presence of boulders, are now available for the dredgers and are yielding large returns. Gold dredging is largely a mechanical problem as is hydraulic mining, but judging from the kinds of machines first used and the character of the ground operated upon it would hardly seem that it was realized. Fully 90 per cent of the early attempts at dredging were deplorable failures, the causes of which were; incompetency; dishonest methods; reckless business management; and careless speculative investment.

The following conditions should obtain in a property suited to gold-dredging operations: paying values in gravels; moderately soft bed-rock which can be readily cut and handled by buckets; moderate depth to bed-rock should not exceed 60 feet below water-level; easy digging ground; plenty of fuel at moderate cost or proximity to electrical power plant; good water supply; long working season; a favorable topography; transportation facilities; and reasonable cost of plant and general equipment. Although the first condition is paramount in importance still it is not the controlling factor as conditions resulting from the failure of any of those named may prove prohibitive.

Supplementary to the above the following statements may be made: Placer ground well suited to dredging, or what may be called ideal ground, may be said to fulfill the following conditions: 1st, depth of deposit not to exceed 25 feet and overlying a soft bed-rock; 2nd, a supply of flowing water equal to at least 20 miner's inches; 3rd, the absence of timber or brush on the ground to be operated on; 4th, not over 5 per cent of boulders in gravel, the largest not weighing over 400 pounds; 5th, gold-content averaging 25 cents or more per cubic yard, being fairly coarse and evenly distributed from top to bottom of the deposit; and 6th, cheap fuel or electrical power. The presence of cemented gravel and clay in considerable quantities may reduce both output and profit, and has often necessitated radical changes in operation and management.

Very large boulders cannot be handled by dredgers, hence in not being able to handle and dispose of them much gravel may be left around and underneath them. With bed-rock that is hard and irregular or full of crevices the gold occurring in the crevices and hollows is lost. The bed-rock must be level enough to permit the movement of the dredger over the whole ground; further, the surface of the gravel bank should be moderately level in order that the head lines may be used to advantage. Swiftly flowing streams, especially when subject to floods, in which there is considerable depth of gravel intermixed with boulders and interstratified with mud, are considered unfavorable to dredging.

Return To:

Historic Placer Mining Technologies