While the wagon-roads were being built, the miners were not idle. Supplies for their use could readily be packed up the mountain, and the rich silver ore, securely sewed up in canvas bags, made convenient return loads for the trains of pack-mules. In a month or two the several companies working on the Comstock discontinued the use of rockers and arastras. The richest of their silver ore was sacked up and sold for shipment to Europe, and that of a lower grade was piled up in dumps and ore-bins to be worked in mills in the country at some future day. The following extract from the Territorial Enterprise, then published as a weekly newspaper at Genoa (it is now published as a daily and weekly at Virginia City, and is the leading paper of the city and state), will give some idea of what was being done three months after the discovery. The item was published on Saturday, October 1, under the title of " The Mines : " " The mines at Virginia Town and Gold Hill are exceeding the most sanguine expectations of their owners. At Virginia Town, particularly, the claims on the main leads promise to excel in richness the far-famed Allison lead in California in its palmiest days. "Claims are changing hands at almost fabulous prices. No fictitious sales either, but bona-fide business operation. The main lead, on which is the celebrated Comstock and other claims, appears to be composed of ores producing both silver and gold, and the more it is prospected the richer it is proving. "

Donald Davidson & Co., of San Francisco, have purchased 200 tons of the rock, containing gold and silver in conjunction, at $2,000 per ton, and are shipping it to England by way of San Francisco, for assay. (Smelting is meant). Other parties are investing heavily. All that are now interested are but making preliminary arrangements for next spring, when we may expect to find an amount of either dust or ore sent from that section that will astonish some of the now incredulous ones in California," They were not only selling and shipping large quantities of ore at this time, but were also beginning to work ores in mills and water-power arastras on the Carson River, near Dayton. In October, 1859, Logan & Holmes had a four stamp mill in operation (by horse-power) at Dayton, which crushed four tons of ore per day, and Messrs. Hastings & Woodworth had two water-power arastras running, which reduced three tons each per day.

The ore being worked by these mills was from Gold Hill, where the ore of the vein as yet contained only gold, they not yet having penetrated to a sufficient depth to reach the silver. In the mines rapid advances were soon made, both in the development of the various claims and in the machinery and appliances used. Whereas, the first shafts sunk were mere round holes, precisely similar in every respect to an ordinary well, now began to be seen well-timbered square shafts of two or more compartments; the old hand-windlasses gave place to horse-whims and to steam hoisting machinery, and large and substantially constructed tunnels took the place of the "coyote holes" which were at first run into the hills.

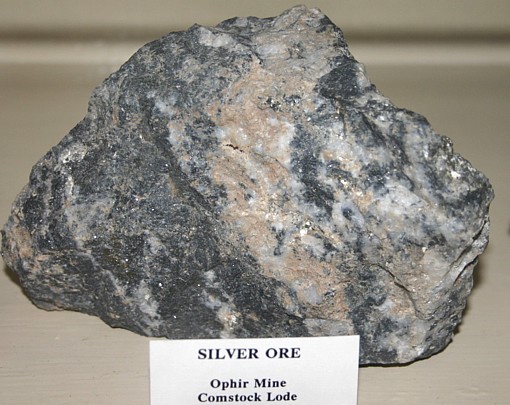

The first steam hoisting and pumping machinery seen on the Comstock lead was put in at the Ophir mine, in 1860. The machinery was driven by a fifteen-horse-power donkey-engine. The mine was at that time being worked through an incline (an inclined shaft) which followed the dip of the vein. A track was laid down in this incline and a car was lowered and hoisted through it by steam-power. The pump then used had a pipe but four inches in diameter, and it was hard work to keep the mine drained, even at the slight depth then attained. In December, 1860, the Ophir folks had attained a depth of but 180 feet in their mine. They were working down in the heart of the bonanza, or rich ore-body, and at that depth the breadth of ore was forty-five feet. No such great width of ore had ever before been seen, and the miners were at their wits' end to know how to work it and keep up the superincumbent ground how to support such a great width of ground with timbers, was the question. The ordinary plan of using posts and caps would not do, as posts of sufficient length could not be obtained, and, even though they could be had, would be inadequate to the support of the great weight and pressure that would be brought to bear upon them.

In this emergency the company sent to California for Mr. Philip Deidesheimer, a gentleman who had had much practical experience both in the mines of Germany and those of the Pacific coast. After Mr. Deidesheimer arrived and was placed in charge of the mine as superintendent, he worked upon the problem before him for three weeks before he arrived at a satisfactory solution. He then hit upon the plan of timbering in "square sets " which is still in use in all the mines on the Comstock, and without which they could not be worked. The plan was to frame timbers and put them together in the shape of cribs, four by five or six feet in size, piling these cribs one upon another but all neatly framed together to any desired height. Thus was the ground supported and braced up in all directions. Where the vein was of great width, a certain number of these cribs could be filled in with waste rock, forming pillars of stone reaching up to the wall of rock to be supported up to the roof of the mine. Previous to the invention by Mr. Deidesheimer of the system of timbering by means of " square sets," the only supports used in the mines were round logs cut on the surrounding hills. These logs were from sixteen to thirty-five feet in length. When of the latter length they were manufactured, that is, were made of two logs spliced and held together by means of iron bolts and bands. Owing to the stunted character of the pines and cedars found in the neighborhood it was almost impossible to procure a log more than twenty feet in length. After setting up two of these long logs, a log about eighteen feet long was placed upon them as a cap. These posts and caps were placed as close together as they could be made to stand, but then would not hold up the ground when it began to slack and swell from exposure to the air. Besides this difficulty there was no safe way of working either above or below these sets, in the vein. To take out ore, either under or over the timbers, loosened them and caused a disastrous cave. Many accidents happened and many men lost their lives while this method of timbering was practiced, but no lives have ever been lost in timbering by the square-set or Deidesheimer plan.

In the mines at Gold Hill was where the timbers thirty five feet in length were used, and there was where the greatest number of accidents happened; but in the Ophir mine, timbers sixteen feet long had been used. When the miners of Gold Hill heard of the new mode of timbering practiced in the Ophir mine, they went up to Virginia to see it, and found it was just what was required. Mr. Deidesheimer sent some of his carpenters down to Gold Hill to show the workmen there how to frame the new timbers, and how to. set them up. In 1861 this style of timbering was adopted along the whole line of the Comstock and has been in use ever since. The Ophir was probably the first mine in any part of the world where such a system of timbering became a necessity, as no ore body of such great width had ever before been found. Nothing seen in the Comstock mines more surprises and pleases the mining men of Europe than this mode of timbering. It is a thing none of them has ever before seen or thought of, and its utility is so strikingly obvious that they can hardly find words in which to adequately express their great admiration of it. In 1861, Mr. Deidesheimer prevailed upon the Ophir Company to put up a forty-five horse-power engine, an eight-inch pump and improved hoisting machinery for the incline of the mine.

The company thought this a fearfully extravagant move, and were almost frightened out of their wits when this " tremendous " machinery was first mentioned. Now there is hardly anything in the shape of a mine anywhere along the Comstock range on which there is not in operation more powerful and costly machinery. At the depth of 180 feet, at what was called the third gallery, the width of the ore was, as I have said, 45 feet ; at the fourth gallery it became 66 feet in width, and the miners were delighted to find that the new timbers supported the ground in the most perfect manner. At this time the ore extracted from this first bonanza was assorted as it was extracted. That which would average $1,000 per ton was sacked up and shipped to England for reduction, while the remainder was piled up as second and third-class ore, to await the erection of proper mills for working it at home. At the Mexican and other mines in the neighborhood, about the same disposition was at this time being made of the ores taken out, while at Gold Hill they had not yet attained a sufficient depth to reach the silver, and were working their gold ores for gold alone; though much silver was obtained with the gold. Return

to The Nevada Mining Rush Page:

Nevada Gold Rush Mining History