THE FOLLOWING INFO IS

PRESENTED FOR ITS HISTORIC VALUE. PROCESSING WITH MERCURY IS NOT

RECOMMENDED.

Properties and Care of Mercury. Mercury is classed as a metal, and as

such is unique in that it is liquid at ordinary temperatures. It is commonly

called quicksilver on account of its color and activity; in mills it is also

spoken of as the 'silver' or the 'quick.' It is 13.6 times heavier than

water. It freezes at -40F. (-40C.). It vaporizes little or not at all at

ordinary temperatures, but the tendency to vaporize becomes greater with

increase of temperature until at 212 F. or the boiling temperature of water

there is danger of salivation in approaching it. It boils at 680F. (360C.).

It is insoluble in water, but violent agitation causes a little of it to be

taken up mechanically in a fine state of division by the water. It combines

chemically with certain substances to form two series of compounds,

mercurous and mercuric as mercurous chloride (Hg2Cl2 ) and mercuric chloride

(HgCl). It combines mechanically with other metals to form alloys called

amalgams, which exhibit some of the characteristics of chemical compounds.

Mercury is readily dissolved by strong nitric acid, and slowly by the dilute

acid. It is not dissolved by hydrochloric acid. It is dissolved by hot

concentrated sulfuric acid, but not by the cold acid. Metallic mercury is

slowly dissolved by weak or strong solutions of potassium cyanide or of

sodium cyanide; the rate of dissolution increasing with the strength of the

solution; the compounds of mercury are more readily attacked by these

solutions.

Mercury alloys directly with most of the metals to form amalgams. When the proportion of the mercury is small, these amalgams are hard, solid, and crystalline ; as the proportion of the mercury increases the amalgam becomes pasty, and finally liquid. Gold amalgam containing 90% of mercury is liquid, with 87.5% pasty, and at 85% mercury the amalgam crystallizes. Gold, silver, copper, lead, zinc, tin, cadmium, bismuth, tellurium, sodium, and potassium unite directly with mercury; the latter two requiring heat to combine actively. Iron, especially when in a fine state of division, can be caused to unite with mercury by means of sodium amalgam. Antimony and arsenic unite with mercury when heated. Chromium, manganese, platinum, aluminum, and nickel will unite with mercury by the employment of the electric current and by other indirect means.

Pure mercury is not affected by the air at ordinary temperatures, but when impure, its surface becomes coated and tarnished with compounds of the base metals, such as oxides, sulfates, chlorides, and sulfides, and probably to some extent by mercuric oxide and sulfide. Impure mercury can readily be recognized, since its surface will appear tarnished instead of bright, and its globules will not be spherical and tend to unite quickly with one another when brought together. When rolled about, the globules will be sluggish and will elongate to a tail and leave a black film behind. Oils and organic substances also tend to render mercury impure. When it breaks up into extremely minute globules which will readily float on water, it is said to be 'floured;' and when these globules refuse to coalesce again, the mercury is said to be 'sickened.' Shaking the mercury in the presence of detrimental substances, or stamping in the mortar, promotes 'flouring,' and in the first case 'sickening' as well. Each one of the “sickened” globules of mercury is surrounded by a film of foreign substance, quite often an oxide or other compound of a base metal.

Various methods are used to restore impure or foul mercury to its normal condition. Cyanide of potassium is beneficial through neutralizing the grease, and abstracting the oxygen from the oxides. Likewise sodium, by its attraction for oxygen, reduces the oxides of the base metals which are coating the globules of mercury; and as sodic oxide is soluble in water, it can be removed by washing, while the base metals enter the mercury forming a base amalgam. After treatment with these powerful alkalies the mercury is in condition to do good work, but owing to the tendency of the base metals to again oxidize, the relief is only temporary; consequently an attempt should be made to remove the base metals entirely. Retorting will accomplish this, if carried on at moderate heat, though probably not completely, as some of the base metals, such lead and zinc, may distill over, particularly at high heat. Purification by chemical means is easier and better. This can be accomplished to some extent by employing sulfuric acid, better by hydrochloric acid, and still better by-nitric acid, the acid being dilute in each case. For this purpose the mercury should be placed in a glass or glazed vessel that will not be attacked by the acid, with a solution of one part nitric acid and from five to ten parts of water, and allowed to remain for at least 48 hours with frequent stirrings that all the base metals may be dissolved. Besides dissolving the base metals that contaminate the mercury, the acid will also dissolve some of the mercury, and should it crystallize, more water and a little acid should be added that the mercuric nitrate may be kept in solution. The mercury in solution as mercuric nitrate will be precipitated when more impure mercury is added, by base metals replacing the mercury to form nitrates of themselves. By suspending a piece of copper in the solution, the mercury in solution can be completely precipitated. The mercury should be washed to remove all traces of the acid before being used. Since impure mercury does not amalgamate gold with the facility that pure mercury does, and as it is liable to become 'floured' and 'sickened' and thereby result in loss of both gold and mercury, as well as to cause base metals to enter the bullion, the purification of the 'quick' should always be given the necessary attention.

Principles of Amalgamation. Mercury 'wets' those substances with which it amalgamates just as water wets an ordinary substance, forming a thin film of amalgam about them by the absorption of the mercury. The surface tension of mercury is very high and its tendency is to pull within itself, or below the surface, any substance that amalgamates with it; in this way the particles of gold arrested on an amalgamating plate disappear below the surface. In the case of those substances with which it does not amalgamate, its surface tension acts negatively and it is strongly repellent to them. In crushing an ore for amalgamation, the aim should be to crush just fine enough to liberate the gold from its matrix of quartz or other mineral, that these golden grains or flakes may be exposed to and caught by the aid of mercury. Crushing too coarse will result in the gold not being liberated, but still enclosed in the gangue rock so that the mercury is unable to reach it. Crushing too fine may result in beating the gold up into flakes so fine that it can hardly be brought into contact with mercury, or may possibly coat it with a film of slime or some constituent of the ore so that it will not readily amalgamate.

Mercury is fed into the mortar that it may come in contact with the gold as soon as liberated from the rock by crushing. The action of the stamps causes the mercury to become finely divided and to be intermingled throughout the pulp, thus 'wetting' a considerable amount of the gold. Part of this gold sinks about the dies as amalgam, part is caught upon the inside plates if any are used, and part passes out through the screen. That gold which comes in contact with the mercury while in the mortar and which passes through the screen, is, by virtue of its being encased in an envelope of mercury or amalgam, larger than the original native golden grain before being coated by the mercury ; this, in connection with the coating of mercury, enables the lip or apron plate easily to catch it. Gold that is not so 'wetted' is harder to catch and may travel farther away from the mortar.

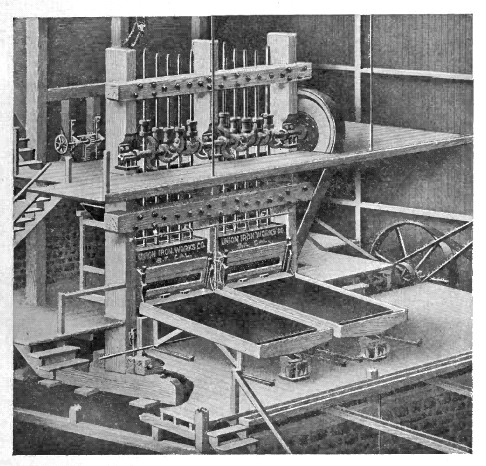

Inside Amalgamating Plates. The part of the gold which is won from the mortar-sand is found, not in the sand resting on the dies when the mortar is opened, but in that below the level of the face of the dies. Where no mercury is fed to the mortar, this will be as coarse gold, but where mercury is fed into the mortar, it will be found as amalgam. The amount of gold retained in the mortars and will vary with the time the gold has been accumulating in the mortar and with the height of discharge. A wide mortar with a high discharge carries double or treble the amount of pulp a narrow mortar with a low discharge will carry. In such a ' wave ' mortar it will be hard for the coarse gold and amalgam to escape as their higher specific gravity will cause them to sink down through the pulp rather than to rise and pass out through the screen, while in the 'splash' mortar they will be thrown through the screen with little regard to their specific gravity. The amount of gold retained in the mortar will also vary with the size of the particles of gold; thus, with fine gold there will be very little caught in the mortars and, while with coarse gold the percentage will be relatively high. The 'chuck-block' is a piece of wood fastened to a strip of the same material, the latter resting beneath the screen in the screen frame slots of the mortar. Its purpose is to fill a portion of the surplus space between the dies and the mortar lip and screen frame. The chuck-block is sometimes lined with a copper amalgamating plate, called a 'front inside plate' or 'chuck-block plate.' Its function is to catch and hold upon its surface as much gold in the form of a hard amalgam as possible. On account of its close proximity to the stamps, this plate is subjected to much scouring action by the pulp, which increases as the chuck-block is moved nearer the stamps, or the height of discharge is lowered, so that mortars for using inside plates were formerly designed to be from 14 to 18 inches across the inside of the mortar at the lip. Chuckblock plates are now very successfully used in narrow mortars only 12 in. wide at the lip by using a high discharge. The height of the chuck-block can be varied by inserting beneath it and in the screen.

Continue on to:

Amalgamation in Cyanide Solution

Return To:

Hard Rock Quartz Mining and Milling