Hard Rock Gold and Silver Mining Topics:

1. Early

California

Quartz Mining

2. The California Quartz Mines

3. Some Quartz Mining Advances Were Finally Made

4. Mining Systems For Working Lode Deposits, Part I

5. Mining Systems For Working Lode Deposits, Part II

6. The Arastra and Chilean Mills

7. The Stamp Mill

8. Principles of Stamp Mill Crushing

9. Gold Milling Operations with Amalgamation and Cyanide

10. Mill Men and Mill Crews

11. Purchasing a Gold Ore Processing Mill

12. Properties and Care of Mercury And Its Amalgamation On Plates

13. Amalgamation in Cyanide Solution

14. Cleaning Amalgam and Clean-Up Procedures

15. Retorting Amalgam and Recovering Gold From Slag

16. Loss of Gold in Amalgamation and its Remedies With Mill Testing

17. Melting and Sampling Dore and Bullion

18. Definitions Of Gold and Silver Mining Terms

19. Old Time Gold Ore Processing Methods

20. Examples of Old Time Milling Processes For Various Ores

21.

Evolution Of

Mining Methods In The North, Part I

22. Evolution Of

Mining Methods In The North, Part II

23. Evolution Of

Mining Methods In The North, Part III

24. Historic Options For Gold Milling Machinery, Part 1

25. Historic Options For Gold Milling Machinery, Part 2

26. Historic Options For Gold Milling Machinery, Part 3

However the process only begins there, as the rock must then be processed to extract the values from the ore. The processing begins with some sort of crushing to release values inside the rock. The early operations used some sort of hammering to break rock down to roughly egg size and then a large stone was dragged around a milling track to reduce the material to sand size. This stone structure was known as an arastra. Later, miners developed a pulverizing iron rod which rose and dropped automatically. Often arranged as a series of these rods, this piece of equipment was known as the stamp mill.

These systems did a good job of breaking up the rock to release its values, but then the miner must recover the valuable minerals. For free native gold particles, simple gravity methods worked well, but amalgamation on a plate surface did a better job of recovering the smallest particles of gold, which in hard rock ore processing can really add up to make a difference.

Often when the miners got down below the level of surface oxidation, much of the gold was encapsulated in sulfide minerals. These make the ore much more difficult to process, requiring steps to oxidize the sulfides before the values could be recovered. Early methods uses natural weathering in what was known as the patio process, but this was very slow and methods of roasting were soon developed. Finally in the 1890s, the use of cyanide to capture gold and silver was perfected.

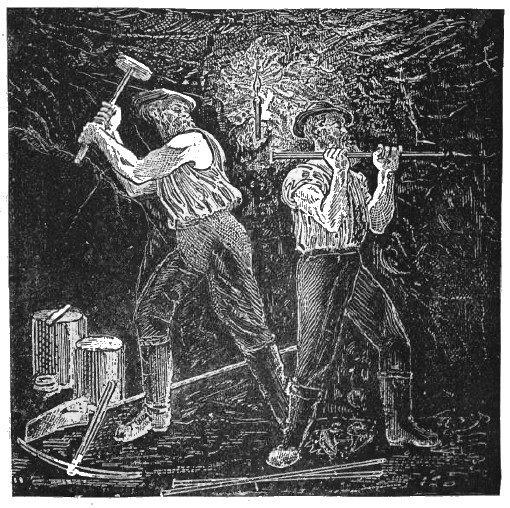

Drilling to blast by candle light using hand steel in the "Double Jack"

method. Black powder is in the tins on the ground to the left.