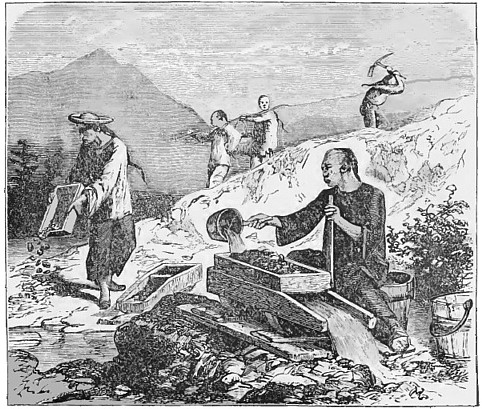

Dry Washing. Dry washing is a method of winnowing gold from dirt. In many parts of the mining districts of California, water cannot be obtained during the summer for mining purposes. The miner therefore manages to wash his dirt without water. He takes only rich dirt, and putting it on a raw hide, he pulverizes all the lumps and picks out the large stones. He then with a large flat basin throws the dirt up into the air, catches it as it comes down, throws it up again, and repeats this operation until nothing but the gold remains. Of course a pleasant breeze, that will carry away the dust, is a great assistance to the operation. Sometimes two men have a hide or a blanket, with which they throw up the dirt. The process is very similar to the ancient method of separating grain from chaff. The miner who devotes himself to dry washing must be very particular to take only rich dirt, so he scrapes the bed-rock carefully. He never digs very deep not more than twenty feet ; and when he goes beyond seven or eight feet he "coyotes," or burrows after the pay-dirt. He may coyote into the side of a hill, or sink a shaft and coyote in all directions from it. This style of mining is named from the resemblance of the holes to the burrows of the coyote, or Californian wolf. Coyote mining is not confined to the dry washing, but is used also by miners washing with the gold pan and cradle. One of the Congressmen elected some years ago to represent California at Washington, was a miner at the time of his nomination, and was so fond of coyoting, that he was generally known as" Coyote Joe."

Dry Digging. Dry digging is that mining where the miner, after using the shovel to strip off the barren dirt, scrapes the paydirt over with a knife, picking out the particles of gold as he comes to them, and throwing away the earthy matter. This is a slow process, but in rich placers may be profitable. The miner is, of course, particular to examine all the crevices in the bed-rock; and if the material be slate, he digs up part of it, to see whether the gold has not found its way into cracks scarcely perceptible on the surface. " Dry digging," as a mode of mining, must not be confounded with "dry diggings," a kind of mining ground which has been described near the beginning of this chapter. Knife-mining differs a little from dry digging. In the latter, a shovel is used to strip off the barren dirt ; whereas the knife mining is practiced in those places where the gold is deposited in crevices in rocks along the banks of streams, without any covering of barren dirt, so that the knife alone is used in scraping out the dirt ; and afterward the dirt, being placed in a pan, may be washed in water, which is never used in dry digging.

Puddling-Box. The puddling-box is a rough wooden box, about a foot deep and six feet square, and is used for dissolving very tough clay. The clay is thrown into the box, with water, and a miner stirs the stuff with a hoe until the clay is all thoroughly dissolved, when he takes a plug from an auger-hole about four inches from the bottom, and lets the thin solution of the clay run off, while the heavier material, including the gold, remains at the bottom. He then puts in the plug again, fills up the box with water, throws in more clay, and repeats the process again and again until night, when he cleans up with a cradle or .pan. The puddling-box is used only in small mining operations, and never with the sluice, or in hydraulic claims. It was strongly favored (and needed) at many locations in Australia.

Rich deep placers may be worked by drifting, but whenever practicable hydraulic mining is to be preferred as giving more profitable results. It yields from four to six times the amount of gold that drifting does. Tunnel-Mining. A tunnel, as practiced during the California gold rush, is an adit or drift entering a hill-side, or running out from a shaft. Mining tunnels are usually nearly horizontal those entering hill-sides having a slight ascent, for the double purpose of draining the mine, and to facilitate the removal of the pay-dirt. In a few hills the tunnels run downward at an angle of twenty degrees or more, to avoid veins or ledges of rock, which would have to be blasted through if the tunnel were cut horizontally; but this can only be done with safety in hills which are drained by older horizontal tunnels. Underground mining is practiced in Alaska for another reason, because the constantly frozen ground will not permit of the more remunerative hydraulic methods. In Alaska and the Yukon, the gravels mined underground were carried to the mouth of the tunnel and there dumped to be washed in the sluices when the weather warms. The mining-tunnel does not run through a hill, but only into it. The length of tunnels varies greatly ; the longest are about a mile. The usual height is seven feet, the width five feet. Ordinarily the top must be supported by timbers, to prevent it from falling in, and not infrequently the sides must also be protected by boards. The cost of cutting a tunnel varies from two to forty dollars a longitudinal foot, according to the nature of the ground, the cost of getting timbers, &c. Tunnels are usually made by companies of eight or ten men, of whom one-half may be merchants, lawyers, physicians or office-holders, and the remainder laboring miners. The latter class do the work ; the former furnish provisions and tools, and a certain amount of cash weekly until the pay-dirt is reached. Two or three men work at a time cutting a tunnel; one or two to dig the earth, and one or two to haul it out. The dirt of the first fifty yards is hauled out in a wheelbarrow; beyond that distance a little tram-way or railroad is laid down, and the dirt is hauled out in cars, pushed by the miners.

It is not customary to use horses. It is common to have two relays of laborers one set working from noon to midnight, the other from midnight to noon. Work in a tunnel is as pleasant at night as in the daytime. When a company is rich, or has many laborers, it may have three relays, each to work eight hours in the twenty-four. It is not uncommon for two companies, owning adjacent claims in a hill, to unite and cut a tunnel on joint account along the dividing line. They go in until they reach the pay-dirt, and then a surveyor is employed to run the line between their claims, and the tunnel is continued through the pay-dirt."" The dirt from the tunnel is washed for the joint account of the two companies. After the dividing line has been established, each company keeps on its own side, and each has its time to use the tram-way. They may also have a joint-stock sluice at the mouth of the tunnel one company having the privilege of using the sluice one week, and the other the next.

All the dirt brought out in a week can readily be washed in a day. The work of taking out the pay-dirt after the main tunnel has been cut, is called "drifting;" and the holes made by the men engaged in it are termed " drifts." The drifts are usually not so high as the tunnels. The large stones and barren dirt obtained in the drifts are piled up here and there to sustain the earth overhead. Sometimes wooden posts are likewise necessary. Shafts. Shafts are used in prospecting, and also in mining, where the claims are deep and cannot be reached by either the hydraulic process or the tunnel. The prospecting shaft is sometimes sunk into hills supposed to be auriferous, where the shaft is far less expensive than the tunnel. After the shaft demonstrates that the dirt is rich, and precisely the altitude at which it lies, a tunnel is cut to strike it. The shaft may be the cheaper for prospecting, but the tunnel is usually the cheaper if any large amount of dirt is to be taken out. The shaft is dug by one man in the hole, and one or two are employed at a windlass in hauling up the dirt. Mining-shafts in placer diggings are rarely over one hundred feet deep ; but one was dug in Trinity county to the depth of six hundred feet, for the purpose of prospecting, but it found neither pay-dirt nor the bed-rock.

Dry-washing consisted in tossing the dirt into the air while the wind was blowing, and thus gradually winnowing out the gold. This method was mostly confined to the Mexicans, and could be used to advantage only in rich diggings devoid of water, where the gold was coarse. The Mexican generally obtained his pay-dirt by 'coyoting;' that is, by sinking a square hole to the bed-rock, and then burrowing from the bottom along the ledge. For burrowing he used a small crowbar, pointed at both ends, and with a big horn spoon he scraped up the loosened pay dirt. This, pounded into dust, he shook with great dexterity from a batea, or wooden bowl, upon an extended hide, repeating the process until the wind had left little of the original mass except the gold. In this manner the otherwise indolent Mexicans often made small fortunes during the dry summer mouths, when the rest of the miners were squandering their gains in the towns.

Continue on to:

River Mining and Ground Sluicing for Gold – Part I

Return To:

Historic Placer Mining Technologies