THE FOLLOWING INFO IS

PRESENTED FOR ITS HISTORIC VALUE. PROCESSING WITH MERCURY IS NOT

RECOMMENDED.

After the amalgam is removed at the daily cleaning of the plates, it is

necessary to clean it by removing the sand, iron, sulfide, and base metal

dross. This is done by grinding it in a wedgewood or iron bowl with enough

mercury to make it quite liquid. The impurities rise to the top, where they

are carried over the side of the bowl into a gold pan in which the bowl

sets, by a stream of water from a hose, or they are taken off by a coarse

sponge. After the quartz and dirt and dross impure and foul amalgam has been

taken off, a magnet is passed through the liquid amalgam several times to

remove the fine iron and steel. It is now poured into a wet canvas or a

double thickness of stout drilling lining a bowl. The cloth is gathered up

by the corners and twisted tight, forcing the liquid mercury through the

fabric and leaving the hard amalgam behind in the cloth. This process of

squeezing or wringing the amalgam is continued, the globules of mercury

being washed off by aid of water into the bowl beneath.

When all the

mercury has been expressed that the operator can wring from it, the cloth is

spread out exposing a ball of hard amalgam within. The ball is rolled around

in the cloth to pick up the, loose flakes of amalgam; after which the ball

is weighed, wrapped in paper on which is usually marked the date and weight,

and locked up until the monthly or semi-monthly retorting and melting.

The mercury passing through the cloth will carry some gold, but this is not considered undesirable as such mercury is more active in promoting amalgamation than that which is gold-free. The amount of gold so retained can be reduced by squeezing the amalgam through a less porous material, such as chamois. Mechanical amalgam squeezers are in use. Their product is not as satisfactory as that produced by hand, but as they work faster and save labor they are suitable where a large amount of amalgam is produced. Where compressed air, steam, or water pressure is available at the mill, they can be rigged up out of an old air rock drill. Some amalgamators clean the amalgam by adding sufficient mercury to make it soft and mushy, when it is dumped upon the upper apron-plate, where it is puddled by the fingers, or a rubber, until it sticks to the plate in one mass. Water is turned on from a hose, which, in connection with the puddling, washes the amalgam clean. After using the magnet, the amalgam is scooped up and transferred to the straining cloth. This is a poor method, though the amount of amalgam lost is small when the treasure box is used; it causes a loss of running time and leaves a wet spot on the plate. The easiest way is to use a gold pan having an amalgamated copper bottom on the inside, when removing the amalgam from the plates. Then, when at leisure, work this amalgam up at the clean-up sink in the same manner as on an apron-plate. Grinding with an excess of mercury in a wedgewood bowl gives the cleanest amalgam. The dross or impure mercury and the rich sulfide collecting from the daily cleaning of the amalgam should be ground with mercury when a quantity has collected. All of the debris and refuse from these cleanings should finally go to the tank of the clean-up sink, to be run through the clean-up barrel or pan later, or sent through the mortars in the absence of a clean-up barrel or pan.

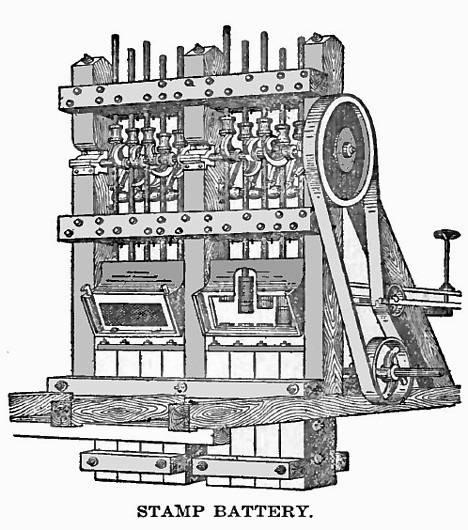

Where there is considerable gold in the mortar sand, this sand is removed once a month or on a general clean-up day. At this time the battery is stamped out and hung up. The apron-plates are cleaned before the mortar is opened. A platform of boards with cleats to fit the apron-table is placed over the first plate to work upon without marring the plate. The screen is removed. The splash, lip, and inside plates are removed to the clean-up room to be chiseled and scraped, which is done by means of old files forged down to chisel ends and ground sharp on a grindstone or emery wheel. A putty knife is a useful tool for this purpose. The pulp lying on the dies is shoveled into boxes or tubs to be returned to the mortar, as it usually contains too little amalgam to be treated. The sand about the dies is dug out with small bars and, together with that underneath the dies, is carried in pails or tubs to the clean-up room, or to the clean-up barrel or pan. The dies are pried up and removed to get the amalgam-bearing sand around and beneath them. All the sand is removed, together with any amalgam adhering to the sides of the mortar or to the shoes and bosses. The dies, which have been washed and examined for any deposits of amalgam, are returned to the mortar. The height of drop is adjusted. The chuck-block, screen, and plates are put in position, and the battery started up.

It is aimed to put the new shoes and dies in at this time whenever possible, and the mercury traps are also then cleaned. Where the amount of gold retained in the mortar sand is too small to make it advisable to lose the running time and the labor necessary to obtain it, the clean-up will consist in scraping the outside and inside mortar-plates and perhaps the apron-plate also; the battery sand being removed and treated only when new dies are put in. At some mills the battery sand from all the mortars, when low in amalgam, is sent through one mortar having a high discharge, and only the sand from this mortar is taken to the clean-up room, but it is not considered good practice. At the clean-up room the sand from the mortars is either panned down in an ordinary gold pan or is run through a rocker to separate and collect the amalgam, the sand tailing being fed through the mortar before the next clean-up.

If a clean-up barrel is used, the mortar and mercury-trap sands, together with that in the clean-up sink from the daily cleaning of the amalgam, are put in the barrel with 40 lb. or more of mercury sufficient to insure the amalgam being liquid also enough water to make a sludge or thick pulp. To this is added a little lye, usually one small can, to 'cut' the grease and keep the mercury in condition; also many pieces of iron and steel to act as grinders or mullers, such as cannon balls, broken stem-ends, and shoe-shanks. Pieces of hard quartz or other rock answer well. The barrel is now revolved from three to eight hours, depending on the ideas of the amalgamator and the time available, at a speed not exceeding fifteen revolutions per minute the higher the speed, the greater the tendency of the amalgam to flour. After grinding, the barrel is slowed down in order that the soft, liquid amalgam may collect ; it is finally stopped with the manhole uppermost and a small plugged opening below. The manhole is opened first to give vent to any gases that may have formed, after which the plug below is removed to allow the amalgam to run into a deep receptacle or pail set underneath. The sand is slowly sluiced out of the barrel with sufficient water to make a thin pulp that will not carry away any amalgam as it overflows the pail. It is run through a coarse screen to remove nails and other small fragments of iron, to riffles and an amalgamated plate for catching any escaped amalgam, and is finally caught in a box or tank. A stamp-mill batea, a large shallow iron bowl or pan which may be characterized as a mechanically-operated gold pan that retains the amalgam and pans off the sand, is superior to riffles or a plate for catching any amalgam that has overflowed the pail. The amalgam recovered is cleaned of iron by the magnet and strained through canvas into balls in the usual manner. The sand is eventually carried back to the mortar as it always contains a little amalgam.

Grinding pans are used at some mills instead of barrels for cleaning the sand and amalgam ; the only variation in the general treatment being that necessitated by the difference in their construction ; both are dispensed with at many mills as they are considered by some to flour the amalgam, while on the other hand some mills are equipped with both. The amalgam chiseled from the plates, or that panned out of the sand, is ground up in a large wedgewood bowl or in an iron hand-mortar with an excess of mercury. Warm water is often used in cleaning the amalgam that it may become softer and liberate more freely the impurities mechanically held or suspended in it, and that it may be squeezed drier. Some amalgamators, though not many, add the amalgam chiseled from the plates at the clean-up to the sand in the barrel and clean it in that way, but it is not good practice to thus take any chances of its being lost or stolen.

Continue on to:

Retorting Amalgam and Recovering Gold From Slag

Return To:

Hard Rock Quartz Mining and Milling