The mill man should have, in addition to training in large and small mills in various localities, and in mechanical work dealing in a general way with the setting up, operating, and repairing of machinery, with carpentering, pipe fitting, and construction work, a short training in assaying and ore-testing, and some study home study if nothing more in chemistry and mechanical and constructive drawing. In view of the wide application of electricity as the motive power for mills, the mill man should understand the use and care of alternating-current machinery. While it is not expected that he should be able to set up transformers or connect the windings of motors, he should understand more than merely to start the motor according to the printed directions. Much has been written and said about the honesty of mill employees. One of the principal arguments advanced for dispensing with amalgamation and centralizing the recovery of gold in the cyanide plant, is that it will prevent loss of amalgam by theft. It has been the fortune of the writer to have worked and associated with many mill men in various parts of the country, and to have come in contact with them on an equal footing and under conditions whereby their character could be best studied, and he has not known of a case of amalgam theft or a suspicion of such, except by report.

There are two reasons why so little thieving occurs, despite the fact that amalgam stealing appears easy and safe. The first is the esprit de corps, or loyalty to the profession, which is as strong in the mill man as in any other calling. The second is that the amalgam or bullion is viewed by the mill man as so much merchandise which he is accumulating for his employer, just as he is saving the sulfide in the concentrating department. It is an actual fact that mill men who may 'high grade' when working in the mine, or on the rock breaker, will take no amalgam from the mill and nothing more than a specimen from the feeders. The danger of amalgam theft lies in putting a green man of unknown character in a mill as helper, or temporarily on clean-up day. Also in the employment of a so-called mill man who is only following milling until he can find an easier way for getting the living that 'the world owes him. Outside of the above two, the danger does not lie mainly with the professional mill employee, but with the dishonest manager, superintendent, or confidential man who does the melting, and who may have a private ingot mold of his own to fill.

In late years a new class of stamp-mill superintendents has arisen; these are the cyanide metallurgists, who, as milling and cyaniding operations are becoming more closely linked together, are taking both operations in charge. Where the work is carried out in conjunction, this is a step in the right direction, but one in advance of the supply, for it is difficult to find men who have a thorough experience in stamp-milling, amalgamation, and cyanidation, mechanically as well as metallurgically. In the extended acquaintanceship of the writer there is only one past master of stamp-milling, amalgamation, and cyanidation, who is able to direct and instruct his subordinates in every detail. The tendency of these new mill superintendents who have little or no training in stamp-milling and amalgamation, is to put too much stress on the cyanide branch. These are the men who would grind all the ore so that the precious metal would be extracted by cyanide solution, disregarding the fact that if a grain of gold is caught on the plates, practically 100% of it is recovered; whereas, if it goes to the cyanide plant, a little of it is lost through the various wastes of solution, the cleaning up, and through the imperfect washings of the filters used. The stamp-battery, to do good work, requires to be in the hands of a man who is in immediate charge of it, one who is a good mill man and a strict disciplinarian, a crank on having everything done right and kept in condition, stopping just short of the point where the details to be carried out become idealistic rather than practical and beneficial. The average competent mill employee prefers to work under these conditions, rather than where no system prevails and everything is racked to pieces so that he must constantly keep a sharp outlook for trouble and be continually repairing. The placing of a stamp-battery in charge of a master mechanic who is not an experienced mill man and whose attention is elsewhere most of the time, is just as serious a mistake as to consign it to the mercy of the different shifts of employees, all of whom are equally responsible and acting without a directing head. A man may be a first-class millwright and machinist and still be unsuited by lack of experience to take charge of a mill. A mistake is made in placing a man in charge of a stamp-battery whose experience has been superficial, no matter how competent he may appear; the result of such error is that the mill gradually wrecks itself until it becomes so badly racked and worn and generally broken down that it is a nightmare for a mill man of long experience to work in it. The stamp-battery is such a simple machine that an observing man can learn to operate it under instruction in a short time, but being ponderous machinery subjected constantly to jar, tremendous vibration, and high tension, to insure long life and good health it must have a man in charge who can promptly recognize its symptoms of trouble and at once apply the proper remedies. From experience and observation it can be stated positively that it is a wise procedure to employ only the highest class of mill men, even if highly priced, for such men increase tonnage and extraction, lessen the cost for repairs, and prolong the life of the mill far more than is generally known.

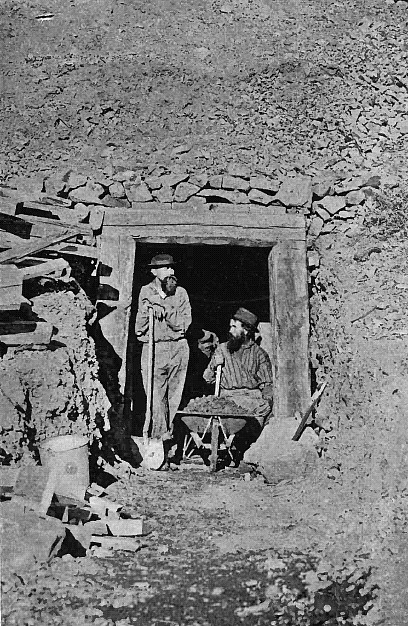

A few words may be added for the novice just entering stamp mill work. Owing to the noise that forbids all conversation except that absolutely necessary, the apprentice must learn largely from observation rather than by direct instruction. Careful, minute, and concentrated observation is the first step, for stamp-milling has become a highly developed craft in which some construction can be placed or some fact read in .details so small that they can hardly be observed by the inexperienced man. By close observation and thoughtful consideration the apprentice is able to observe these details and interpret their meaning, so that in a short time his attention becomes subconscious and therefore no longer forced. He learns to wear engineer's coats or 'jumpers' worn as a shirt, or other tight-fitting clothes that offer no loose ends to be caught by belts and machinery; to use methods that are not unnecessarily dangerous to life and limb in putting belts off and on, hanging up stamps, setting tappets, and working on the stamps; to never drop a stamp until he is sure that no one at the mortar below will be caught or injured by it, etc. The mill man operates his mill largely by sight and sound. As he walks by the stamps, even though at some distance and with his attention preoccupied, he notes any stamp that is dropping too hard or that is too much cushioned; a stem that has pulled out of its boss, or has lost its shoe, or is dropping on a piece of steel that has inadvertently fallen into the mortar; a mortar that is running empty; the coarse oversize due to a break in a screen ; or any of the details that may need remedying. Amid the awful roar he is able to differentiate the sound of improperly working parts from those working properly.

If, while he is in a distant part of the mill shoveling ore in an almost empty bin, working in the clean-up room, or talking to a friend outside the mill door, a stamp breaks, pulls out, or commences to fall on a piece of vagrant steel, a tappet begins to cam, or a mortar to run empty, his trained subconscious mind recognizes the peculiar jangle, or steady clap-clap, or muffled hollow roar, and before he realizes it he is started and perhaps half way across the mill on his way to the seat of trouble, though as a mill becomes racked and worn from poor condition and ill use it becomes more difficult to run by sound. As the steam engineer judges the condition his engine is in by its movement and sound, so does the mill man judge his mill; but unfortunately, the fact that the stamp-mill will stand up to use and abuse as well as answer to the refined control of a master hand has led many to consider the stamp-battery as a relic of medievalism, fit only to be presided over by a low-browed, strong-armed giant equipped with a sledge-hammer and an inexhaustible stock of profanity and endurance.

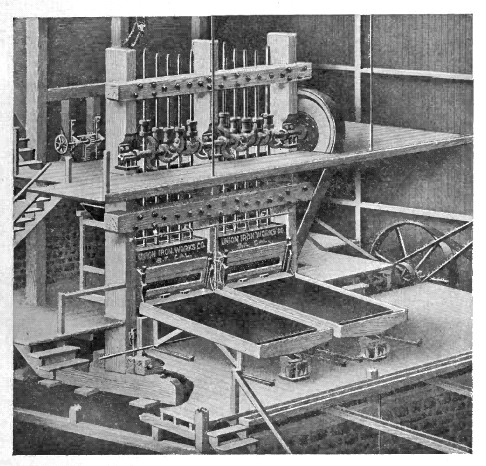

The crew of a 10-stamp mill having concentrators will be composed of one man per shift. The man on the day shift will be in charge and assisted by the man who tends the rock-breaker. A 20-stamp mill with concentrators has been run by the same size crew, but the work is so strenuous that men will not long remain and the company suffers a direct loss during their stay from poor work, especially in the concentration. One battery man per shift with a head mill man can run 40 stamps and do the amalgamating; and for this reason it is an economical size of mill to build. One man per shift has run up to 60 stamps and done the amalgamating, but the work is entirely too arduous for one. The crew of a 100 stamp mill will consist of an amalgamator in charge of the shift, one battery man who attends to the feeding, and one helper. On the day shift there may be a repair man in addition to the head mill man. Should the gold ore be low grade, requiring only one or two dressings of the plates in 24 hours, and the mill be in first-class condition, the helper on each shift may be dispensed with. Should amalgamation not be practiced, the amalgamator may be dispensed with, leaving one man the battery man in charge of the 100 stamps; but a first class mill kept in splendid condition is required if one battery man per shift with a head mill man and a repair man on the day shift are to operate and keep in. repair 100 stamps. The mill wood work, such as making screen-frames, chuck-blocks, and other small matters of this kind, is done in the mine carpenter shop.

It is always advisable to place the mine air compressor in the mill of a small or moderate size property unless there are urgent reasons for placing it elsewhere preferably on the plate floor if there is no steam engineer to take charge of it, since for some inherent reason not readily explainable or through custom the battery man rather than the concentrator man seems to be the proper individual to care for it. The mistake of isolating the air compressor, which requires a constant but small amount of attention, at a point where a compressor man is required to watch it when it could just as well be cared for by one of the mill employees, is often observed. Cases have been noted where the compressor has been located under the same roof as the mill, but in a room so distant from the mill machinery that neither the mill man or the compressor man could assist each other. If the compressor is placed on the plate floor, a separate room should be provided to reduce the tendency for dust to settle on the compressor and in the moving parts. If located on the concentrator floor it is generally not necessary to house it off, as usually very little dust reaches the concentrator floor.

Return To:

Hard Rock Quartz Mining and Milling