In connection with this

matter it should be remarked that the Wilfley table, the Luhrig vanner, and

such machines which separate minerals into bands or strips in accordance

with their specific gravities, are open to objection when the treatment of

such material requires that it eventually be roasted. For instance, bands of

galena,

arsenopyrite,

pyrite and

sphalerite form on the table

or vanner, and drop into boxes as separate products. These never become

properly mixed, and the particles often become lumped together. Galena, as a

rule, accompanies the gold, and hence is the richest of the concentrates.

When roasted a portion of the lead sulfide becomes lead sulfate, and also

lead oxide. These react with the core of unaltered

galena, producing some

metallic lead.

PbS + PbSO4 = 2Pb + 2SO2 , and PbS + 2PbO = 3Pb + SO2.

The lead so produced gathers up adjoining particles of gold. When this

passes through the furnace it may come out as metallic lead, in which case

the gold it contains cannot be dissolved either by cyanide solutions or even

with chlorine. If the roasting is prolonged

the lead

oxidizes, and the oxide of lead fuses and coats adjoining particles, leaving

a minute sphere of gold or silver covered with a glaze.

This material also is no:

attacked appreciably by solutions. The tendency for this effect is greatest

when the gold and lead are close. If the small amount of galena present were

distributed through the concentrates, and if finely ground, the effect is

much less. Again, arsenic compounds lose their arsenic, and antimony

compounds their antimony, and these become oxidized much more readily when

sulfur is present in excess.

The tendency of sulfur is to form volatile compounds with, both of the

elements mentioned. These compounds become oxidized immediately they reach

the hot air, and are either swept awry or rendered harmless. When pyrites in

excess are thoroughly mixed with arsenical pyrites or arsenical compounds,

the latter are amongst the easiest ores to roast. Zinc sulfide also is

converted into sulfate much more easily in contact with pyrites than when

separate. An ore running a few pennyweights per ton, with a small percentage

of pyrites, the bulk of the gold being in the pyrites is naturally one

suited for concentration. If the concentrates produced amount to about 18 to

20 tons per week, it would be as well to treat them on the spot, provided

conditions are favorable. If they amount to a much larger quantity, then,

unless very near customs works, it should pay to treat them at the mine. If

this quantity of pyrites is produced, and it is desired to sell to the

smelters, it is better to erect a furnace and rapidly roast the

concentrates. The whole of the arsenic may be expelled, and the sulfur

brought down to a very lo>w amount for a few shillings per ton. As much as

25 per cent, saving on freight and more than that on the charges per ton for

smelting may be effected. There is really no reason, except in a few

instances, why gold should not be produced from such material by

chlorination or cyaniding at as low a cost as smelting. The main trouble is

to secure men who are competent to carry on this branch of the work. The

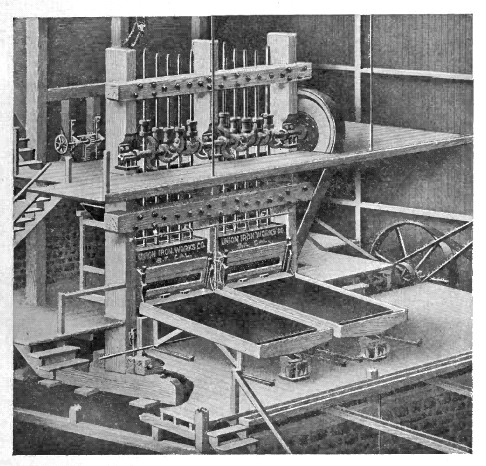

following furnishes approximate prices for the cost of a mill for any

out-of-the-way mine on the lines previously suggested 20 N.H.P. Cornish flue

boiler for 100lb. working pressure... 200

30 N.H.P. Cornish flue

boiler for 100lb. working pressure ... 275

20 N.H.P. horizontal side

valve engine, with governor 275

Compound engine, with governor complete 350 10-head iron-framed stamp mill battery, 1100lb. stamps, 5-head belt driven from underneath counter shaft, with cross-keyed tappets, etc., complete 600 Copper plate tables, with 20 feet copper for each 5-head 40 30-inch Berdan pan and framing complete 20 Concentrating table, complete 125 Grinding pan, 4 feet 6 inches diameter 50 The cost of a suitable stonebreaker would amount to from 50 to 70. An automatic ore feeder could be made for 10 complete. In addition to this, shafting, belting, and pulleys would absorb about 120. The cost of carriage, sheds, and foundations, and erection would cost from half to as much as the plant. Roughly speaking, a 10-head battery, with appliances indicated, would cost from 1000 to 1500. Ordinary battery practice does not need much discussion. The work is for the most part simple and mechanical. In Victoria, Australia, especially at Bendigo, crushing is cheaply done, but costs would be a good deal less than they are if stonebreakers, feeders, and more modern types of batteries were erected. For small mills it is of no use procuring extra machinery where the same number of men are employed with or without it, unless the extra machinery means a reasonable reduction of costs per ton.

No 10-head or larger battery, crushing regularly, should be without a stonebreaker, grizzly and automatic feeders. The stamps, as before indicated, should not be less than 1000lb. in weight. Whether inside amalgamation by means of copper plates is practiced in the box or not is largely a matter of taste. In general it is advisable to feed mercury into the box except with heavily mineralized gold ores. The amount fed in should be 2J times the weight of gold liberated. That is, if stone is crushing 2oz. per ton, and a ton is crushed in a 5-head battery in an hour, then 2 x 2, or 5oz., of mercury should be fed in per hour. If the stone runs one ounce per ton, then 5oz. mercury in two hours will suffice. An even, regular feed along the length of the box should be supplied. The state of the outside plate will generally indicate the proper amount to feed in ; if this plate is sloppy, too much is passing in to the box ; if dry, too little. Very little care is usually exercised in packing a box; in many cases the rubbish from the last clean up is shoveled back again, making the box foul from the start. Clean, angular pieces should be wedged between the dies, leaving room for any amalgam or gold to lodge. Amalgam will always get into every crevice in a rich crushing, and the provision made by some makers in having liners with ripples cast in them appears to be good, although I never had any experience with them. From 3 to 5 gallons of water per stamp mill per minute are used in ordinary practice; in this matter it is better to use about two-thirds of the total amount by supplying each stamp evenly and to apply the remainder or one-third after the sand has left the first copper plate. The pulp will not be thinned too much in the box; most of the amalgam passing through the screens will be caught on the top plate, the overflow from the box serving to carry it this far in a series of pulsations. The water to prevent the lodgment of sand on the remaining plates can be evenly supplied across the table. If plates are properly laid, well amalgamated, and attended to, wells are unnecessary.

All that need be said about concentration of gold ores is that concentrators which are well adapted for saving minerals of high specific gravity will not do corresponding work on gold ores. For instance, if the gold is all in or attached to pyrite, then the saving of the pyrites is what should be aimed at ; but where the gold is excessively fine, especially when associated with clays, slates, the graphite pug so common in reefs, or even with limonite, then concentration will never give results that should be obtained by other means. The losses in the slimes are particularly heavy, and saving of gold means practically the saving of the whole of the slimes. Fortunately the modern doctrine "slime everything and extract the metals chemically" has transformed the old-time trouble into a positive advantage. Any well designed plant of any magnitude should have provision made for slime treatment from the outset. A hydraulic separator could be used to wash the slimes from the sand ; the slimes should then be thickened up in a short series of spitzkasten; the pulp drawn off at the spitzkasten will contain 45 per cent, of solid matter. This should be run into an agitator, dilute solutions of cyanide added, and stirred or agitated with air until the gold is dissolved. A small amount of lime should be fed in with the ore at the battery; this will facilitate settlement in the spitzkasten. For ordinary low-grade slimes agitation followed by decantation, after the manner practised at the South German mine, Maldon, or preferably after the manner suggested by Mr. Frank Moss, of the Kalgurli mine, would be economical and effective.

The overflow from the spitzkasten, containing a very small quantity of slimes, should be returned to the battery. In most cases with our ores, if the slimes are well separated from the sands, the latter are too poor to treat. In certain rare cases, where the coarse material which escapes is as rich as the fines, then as a rule a preliminary grinding must be applied before the sands are cyanided; otherwise the extractions may be very poor. If a small quantity of rich slimes requires treatment, the simplest plan is to first dehydrate them by a rapid roast, put a layer of coarse sand in the bottom of a vat, a layer of about two feet of the slimes above it, and then a foot of coarse sand over this. Solutions may be passed upwards which will come through the upper layer of sand absolutely clear, not clogging it in the slightest. Even sun baked slimes may be treated very often in this way, whereas they would be absolutely impervious if dumped into vats in the ordinary way. As a rule, the amount of true slimes from pan grinding is the bulk of the ground material may be treated by percolation. In case pyrites require to be roasted and treated by cyanide or chlorination, the form of furnace selected is important. For small mines roasting from one to two tons per shift, the furnace made by Jaques Bros., Richmond is simple and effective.

It may be driven by an oil engine, and requires but little attention. Sometimes the cost of any mechanical furnace is too great; in that case a simple hand-rabbled reverberatory is sufficient; there are many types of these, mostly bad. The furnace described in the article on Bethanga is the best for the class of work in Australia. Through the courtesy of Mr. A. H. Merrin, Queen-street, Melbourne, the following particulars of the reverberatories designed by him for the Cassilis G.M. Co., Gippsland (V.), were obtained: Outside width, 10 feet; width of hearth, 7 feet 9 inches; spring in arch, 2 inches; height of arch at centre, 10 inches; pitch of first hearth, 3 feet in 26 feet; pitch of top hearth, 1 foot 9 inches in 26 feet; width of discharge hopper, 10 inches. These dimensions, together with the notes on the Bethanga furnaces, will give the essential details for the construction of such a furnace. Fire bricks can be made on the ground, the total cost, independent of the stack and flues, amounts to only about 120. If the gold ore contains pyrites running about 20 per cent, of sulfur, about a ton per shift can be thoroughly roasted. If very heavily mineralized, about two-thirds of a ton per shift. More than double that quantity could be put through ita roast free from magnetics were not required, the ore being freed from its sulfur in less than half the time it takes to roast it thoroughly. The furnace is just as large as can be managed by a single workman. The lowness and flathess of the arch is in marked contrast to most furnaces in operation, but experience proves that it is quite high enough, and a great economy of fuel is affected.

Continue on to:

Historic Options For Gold Milling Machinery, Part 3

Return To:

Hard Rock Quartz Mining and Milling