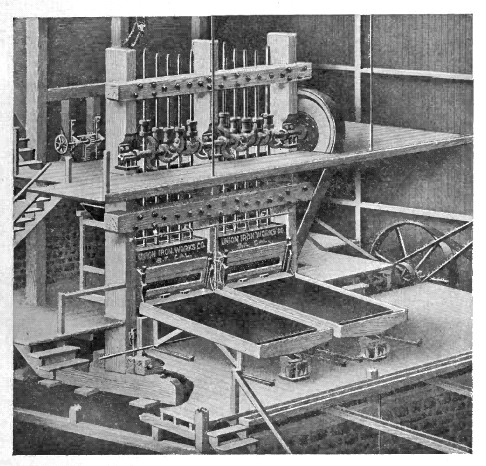

When a mine has been prospected sufficiently to warrant the erection of machinery, the question as to what class of machinery is most suitable should be considered. A great deal of experience is needed to determine this in some cases. If the gold ore is free milling and the percentage of concentrates low, then adopt the simplest methods in this case wet crushing and amalgamation. Many experiments have been tried with various wet crushers, but so far there is no all-round machine which will equal the ordinary stamp mill battery. It is a mistake to get light stamps. Let them be 1000lb. or over, and all parts proportionately heavy. The argument in favor of light machinery for carting should not be made too much of. The carting may cost a few pounds extra, but the saving on the first month's run will more than make this up. When away from a town or facilities for obtaining skilled labor, everything should be of the simplest and strongest. For instance, where mine or any hard water has to be used do not get multi-tubular boilers, for the extra consumption of fuel will cost less than stoppages and repairs for tubes. For similar reasons get belt-driven in preference to spur-gearing. Assuming there is about 2 or 3 per cent, of concentrates in the ore, it will generally be advisable to have a concentrator, preferably one of the Wilfley type. There are others as good as this, but as a rule they are more delicate in construction, and require much more care.

The Wilfley table will remove most of the coarse concentrates, any free coarse natural gold or amalgam that may have escaped. The sands, as a rule, are very poor after passing over the Wilfley, but the slimes, which will amount to from 40 to 50 per cent, of the total material, may carry high values. Very little gold or mineral from these is recovered on such a concentrator as the Wilfley. The sizing of such slimes by spitzkasten and their subsequent concentration is not advisable. Some of their values might be obtained by simply running them over long, slightly inclined canvas strakes. In all oases, it is inadvisable to run either sand or slimes to waste, for although they may be unprofitable to-day, to-morrow they may be a valuable asset. If the gold is coarse and easily amalgamated, it is better to pay special attention to this branch of work rather than go in for cyaniding. In many cases, if amalgamation methods are properly carried out, the tailings are too poor to cyanide, while if the former operation is carelessly done, then the tailings may be rich enough to cyanide, but nothing like the same profit can be made. When the gold is fine, it is not possible to get the whole of it by amalgamation. Even when in quartz it is not uncommon to have tailings running up to an ounce per ton after passing over concentrators. The gold in this case is encased by the grains of sand. This may be readily proved by first panning off a sample, then grinding finely, and panning off again. When clear quartz runs up to separate. By putting on finer screens, matters are not improved, for beyond a certain limit as much is transferred to the slimes a is liberated from the sand. Even by pan amalgamation with fine grinding, only a comparatively low extraction can be obtained by grinding and chlorinating or cyaniding an almost perfect solution of gold may be effected.

One of the most troublesome materials to win gold from by ordinary amalgamation is ironstone. This is specially true when the gold is fine and the gangue is clayey. In most instances from 25 to 40 per cent, of the gold may be amalgamated; very little is caught on the concentrators, but a large portion passes into the sands and slimes. This material is best treated by calcining it; then cyaniding or chlorinating. There is a common belief that by slow running more gold may be obtained by amalgamation. By testing many parcels of ore with a 5-head battery, and making regular assays of the tails, the results always came out very early the same, generally slightly in favor of fast running. The gold ore above water level is generally called free milling, one of those misleading terms based on the assumption that because the ore is oxidized, the gold may be readily extracted by amalgamation, while any ore containing sulfides and other unoxidized minerals is placed in another class. As a matter of fact, a great many sulfide bearing auriferous ores will yield their gold more readily to amalgamation processes than will some of the so-called free milling. In most Cases the gold present is in quartz or in small pieces mixed with metallic minerals. On crushing, the gold, if freed and not too fine, will amalgamate. That which escapes is free natural gold, and will be caught on concentrators with a large amount of barren pyrite. The pyrites may be altogether free from gold, and yet 1 the mixture may assay 3 or 4oz. of gold per ton. In this case good extractions may be obtained by simply cyaniding the material. Pyrites, arsenical pyrites, sphalerite and galena may sometimes in this way be treated, and excellent returns obtained at a low cost. Experiments should always be made to test this before expensive works are erected. In many cases, the gold in pyritic ore is very fine, and evenly disseminated through certain minerals. For instance, pyrites are present only, all the gold may be in or on the surface of these, and none in the stone; if arsenical pyrites are present there will generally be more in the arsenical; while if sphalerite or zinc sulfide occurs, the gold clings to it by some process of natural selection, the silver going to the galena. In this case, the simplest method is to grind the materials finely, thereby liberating the enclosed gold; then treat with cyanide.

Unless compounds of gold, such as tellurides like calaverite, are present, extractions may be obtained which are in proportion to the fineness of grinding. The trouble, as a rule, with this method is not to get the gold into solution, but to separate the whole of the solution from the slimes. Even after very fine grinding a large proportion of such concentrates may be treated in vats, for the product, though fine, is still leachable, but the true floating slimes from the battery, and those from the overflow of the grinders used for the concentrates, are impenetrable. It may be indicated at this stage that such slimes may be treated by first roasting them raw with cyanide solutions, and filter pressing, or by agitating them with dilute cyanide solutions, and then decanting them. In all cases if slimes are worth treating provision should be made for so doing when the crushing plant is erected. When a reef carries a high percentage of pyrites rich in gold, it may be more economical to concentrate the pyritic material, roast it, and then treat the roasted stuff with either chlorine or cyanide solutions. It may prove just as cheap to roast some pyrites as to grind them sufficiently fine for a good extraction. The subsequent cost is less on account of the possibility of direct treatment in vats. The objections to roasting certain classes of ore is that if not properly performed a large amount of chlorine or cyanide is used up, and bad extractions obtained, while even in some cases if the roasting has been carried on perfectly, reactions or changes occur whereby some of the gold becomes locked up, and no solvent, such as chlorine or cyanide, will remove it. Curiously enough, even after finely grinding the roasted material and agitating it with cyanide or chlorine solutions, such gold from a particular mine would not dissolve. Yet if the original ore were slimed and cyanided almost the whole of the gold could be removed.

No hard and fast rule can be laid down; each case must be decided after careful experimental work. When the metallic mineral contents of a lode amounts to 30 per cent, or more, and the gold is associated with this mineral, then bulk treatment is advisable. The slimes produced, amounting as a rule to more than 40 per cent, of the material, would have the same or higher values than the original gold ore. The concentrates would need dilution with sand for an effective roast, while the small quantity of sand discarded would also carry a percentage of gold which would be lost, or additional expense incurred by cyaniding it separately. If ore is to be treated in bulk it should be dry crushed. Wet crushing is slightly cheaper, but a separation of sand, slimes and mineral is always effected. With dry crushing all materials are evenly mixed, which leads to uniform work in roasting, and also in the even percolation of solutions when the roasted material is placed in vats. By such a method of treatment the whole of the fine gold can be dissolved out, and it is questionable whether such material, after all the fine gold has been removed, could not be more effectively treated by amalgamation over copper plates, thence over concentrators to remove any coarse gold, than by removing the coarse gold first, and dealing with the slimes afterwards.

The slime trouble would certainly not exist, while any coarse sands could be saved by classifiers if gold was still locked up, and any fused particles or specks of coarse gold would be caught on the concentrators or amalgamated. In case an ore, even when heavily mineralized, contains a notable percentage to galena, it may not be advisable to dry crush and roast the whole of the material. In this case, it will be better to crush through coarse screens in an ordinary stamp mill battery, and remove the strip of galena carrying gold, which appears on the edge of the Wilfley. A wider strip than necessary may be taken off at first, since the galena band moves laterally as the contents fed on to the table vary. By placing a dividing line so that galena always is caught a good deal of other concentrated minerals come over also. This material should be redressed by feeding it on to a separate Wilfley evenly. In this way, a clean strip of galena may be taken off, which contains a large amount of free natural gold. This may be ground in Berdan pans, and the overflow, still containing high values in gold, sold to the smelters. The lead present will usually defray all costs, the gold and silver being profit. In any mine where galena is abundant this method of treatment commends itself. The slimes resulting from the wet crushing should be cyanided at the same lime as produced. This may easily be done by first thickening the pulp in spitzkasten, agitating and cyaniding. If poor, they should be treated by decantation; if rich, by filter pressing.

Continue on to:

Historic Options For Gold Milling Machinery, Part 2

Return To:

Hard Rock Quartz Mining and Milling