The first seventeen of

these examples are recommended by Fraser and Chalmers, manufacturers of

mining machinery in Chicago.

1. For free

gold that can be panned out and no

sulfides. Wet stamping and quicksilver (mercury) covered

copper plates. In the Black Hill $8 ore yields good returns, in the pioneer

days, milling only costing 60 cents per ton of ore.

2. Free gold with sulfides. By sulfides are meant iron and copper

pyrites,

galena, blende.

Tellurides, selenides, antimonides may also occur with these

ores together perhaps with silver. Wet stamping and catching the products in

blankets or hides. Subsequent treatment in a pan or

arastra. A better method is, wet stamping and quicksilvered (mercury

covered) copper plates. The tailings are treated on a vanning machine (two

of Frues vanners to 5 heads of stamps) subsequent roasting, treatment with

chlorine gas and lixiviation with water, the gold being precipitated with

ferrous sulfate. Chlorination costs 8 to 10 $ per ton of concentrates.

Another process is to roast and amalgamate in pans.

3. Free

gold in small quantity but with much silver in the

sulfides: Roasting milling or free gold milling with Vanners for the

tailings and subsequently smelting. Sulfides foul amalgam. When these are

present dry stamping, mixing with salt, roasting to form chlorides and then

lixivation. The alternative is to smelt the concentrates.

4. Chloride of silver,

native silver and decomposed portions of silver vein out crops

containing over 6 oz per ton. Free silver milling.

5.

Silver ores, partly chloride and partly silver bearing

sulfides. Free milling, Vanners and smelting (see No. 3). For

high grade ore, roasting milling (see No. 3).

6.

Silver ores with base metal sulfides if low grade.

Fine concentration and smelting or for higher grade, roasting and milling.

By fine concentration is meant fine crushing and treatment on Frue Vanners,

revolving buddies, Evan's slime table, Rittinger's tables, end blow tables

or some form of slime machine. The process costs $1 to $2.50 per ton.

Smelting cost up to $30 per ton.

7. Low grade silver ores with gray copper, ruby, bridle or native silver.

Fine concentration and smelting.

8. Heavy mineralized ores of lead, copper, zinc often carrying silver.

Fine concentration and smelting.

9. Highly mineralized ores of lead, copper and zinc. Fine

concentration and smelting.

10. Carbonate or oxide of lead and copper. Direct smelting.

11. Solid

galena. Hand selection or coarse concentration and smelting.

Coarse concentration means, coarse crushing, sizing on revolving screens,

jigging and treatment of slimes on a slime machine. In Western camps it

costs S1 to $3 per ton.

12. Metallic copper ores. Stamping, coarse concentration and melting

to ingot.

13. Antimony ores. Hand picking, concentration and smelting for

metal.

14.

Sphalerite and zinc carbonate. Coarse or fine

concentration and reduction by zinc smelting process.

15. Tin ores. Fine concetration, roasting and smelting.

16. Copper pyrites, copper glance. Hand picking, concentration,

partial roasting and matting; or if convenient selected and concentrated

products are sent to refineries. If of low grade, lixivation for copper and

silver.

17. Heavy iron

pyrites carrying gold. Chlorination process or roasting and

intermixing with ores for smelting.

18. For lead, silver lead, with blende, pyrites &c. The following

installation may be employed: Crushing rolls, revolving classifier, the

coarse material from which returns to the rolls. The remaining material is

sized and delivered to corresponding jigging machines. The slimes pass to

pointed boxes and the coarsest of these may go to fine jiggers or the whole

of them to a rotating buddle. George Green of Aberystwyth recommends for a

capacity of 15 tons per day, .3 self acting, jiggers, 3 patent classifiers

and 3 round buddies. (With wooden hutches jiggers cost 270, with iron

hutches $310). (Rolls 28 inches X 16. inches capacity per day of 35 tons,

cost $140).

19. Port Philip Company, Climes, Victoria. Ore, gold quartz with pyrites.

Machines, Two Appleton's rock breakers. Stamps 80 heads, square heads 6

to 8 cwts each. Grates thick copper plates with 84 holes' to sq. in.,

buddies to collect pyrites each 24 feet diameter, 5 amalgamating barrels.

Shaking table. Two Chilian Mills for grinding roasted pyrites, one 24 inches

cylinder engine 60 H. P. working up to 120 //. P.

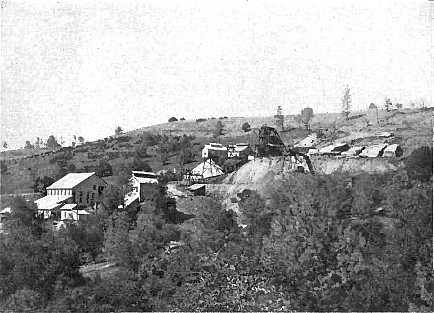

20. Defiance mills. Charters Towers, Queensland. Ore, gold quartz

with pyrites. Machines, Battery 25 heads. Quicksilvered copper plates,

shaking table and plates, convex buddle, sands entering at periphery, with

Mondy's patent scrapers, Wheeler's pans and Berdan pans.

21. Mount Bishoff, Tasmania. Ore, tin stone in loose soil which is

dressed from 1 or 2 per cent up to 72^%. The ore is first roughly washed in

sluices, the coarse stuff going to three mills.

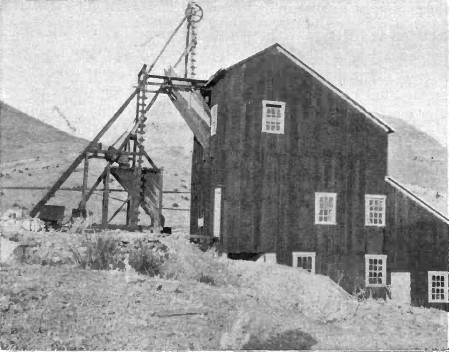

Specifications of a

Twenty Stamp Gold Quartz

Stamp Mill for the Buchanan mine, Tuolumne County, California.

J. Hamilton - One (1) Grizzly, to be made off inch by 2 inch wrought

iron, 12 feet long, 4 feet wide spaced 2 inches between the bars, and

secured by three inch bolts, and cast-iron thimbles and washers; also end

bars. Rock Breaker. One Blake crusher, fitted with two flywheels, 4 feet in

diameter, and one (1) pulley, 30 inches in diameter, and 12 inch face

crankshaft, to have outboard bearings; holding-down bolts for each, to be

long enough for 14 inch timbers ; all caps for boxes to be fitted to use

zinc oil cups, and "Albany" lubricating compound. Battery. Four (4) single

discharge gold mortars, each weighing about 5,000 pounds; the bottoms to be

6 inches thick; well planed ; the screw frame bearings to be planed also;

the bases to be 26 inches wide, 3 inches thick, and cored for eight (8)

mortar bolts 2 inches in diameter ; the feed mouth to be 26 inches long and

3 inches wide, at the smallest part ; the mortars to be well finished, and

to be 56 inches long, and about 52 inches high. Mortar Bolts. Thirty-two

(32) mortar bolts, 2 inches in diameter, and 36 inches long; nuts on both

ends, and thirty-two (32) 4 inch square countersunk washers for the lower

ends; one (1) wrought-iron wrench; jaw designed for the nuts of mortar

bolts; arm to be 6 feet long, slightly curved, made of 1 inch by 2 inch

iron. Stamp Dies. Stamp dies, 7 inches deep, 8-1 inches in diameter, with

square bases, having beveled corners, and all made to properly fit the

mortars, and to be cast of the best car-wheel iron ; stamps to weigh 850

pounds each. Shoes. Twenty (20) stamp shoes, 8 inches in diameter, 7 inches

long; to be cast of the best car-wheel iron. Heads. Twenty (20) stamp heads,

8 inches in diameter, 18 inches long; keyholes to be 1 inches by 3 inches ;

one (1) key for driving out shoes and stems, and to be made as may be

directed.

Tappets. Twenty (20) double-faced gib tappets, made of the best steel faces, 9 inches in diameter; tappets to be 12 inches long; bands or flanges turned, and each to have gibs and three (3) steel keys, and all to be marked ; keys to be boxed for shipment. Cains. Twenty (20) double-armed cams, made of best steel; ten (10) to be right, and ten (10) to be left-handed; hubs on one side, and to be strongly banded with J inch by 2 inches wrought iron bands, well shrunk on ; the faces of the cams to be well smoothed, and to be fitted to 5 inches cam shafts, and to be properly marked. Feeders. Four (4) Hendy Challenge ore feeders, complete with all latest improvements; also, twenty (20) steel keys for same, to be marked and fitted, and properly boxed for shipment; the cams to be about 32 inches long, with 2-k inches face, and struck to give an & inches drop if required. Corner Boxes. Six (6) corner boxes, for 5 inches cam shafts; cored for I inch bolts; backs to be planed true, and bearings to have a strip running lengthwise, and the balance of the bearings to be well babbitted and bored : the ends to be faced; the cap to be solid, bored, but not babbitted, unless required, and bored with three (3) inch holes each, for using "Albany" compound. Cam Shaft;. Two (2) cam shafts, 5 inches in diameter, and 14 feet 6 inches long, and key-seated between bearings. Jack Shafts. Four (4) jack shafts to be 3 inches in diameter and 59 inches long, with eight (8) bearings for same, and to be made of cast-iron. Stems. Twenty (20) stamp stems 3 inches in diameter, 14 feet long; turned and. tapered oft" both ends for heads ; made of rolled iron. Latch-sockets. Twenty (20) open latch-sockets; all to be well lined with heavy leather. Guides. For (4) complete sets of best white oak guides. The lower guides to be 16 inches wide and 4 inches thick, and the upper to be 14 inches wide and 4 inches thick ; bored for 3 inches stamp stems, and to be 10 inches between centers ; all to be 60 inches long. Cam-shaft Pulleys. Two (2) wood pulleys, 72 inches in diameter, with 16 inches faces and 6 inches thickness of wood between the flanges, and to be made of the best kiln dried sugar pine; to be turned and well bolted to 40 inches diameter cast-iron sleeves ; flanges for 5 inches cam shaft; the flanges to be faced. All of the keys for this mill to be made of the best steel. Overhead Crabs. One (i) crab for battery having flanged wheels 7 inches in diameter and 2 feet face ; the axles to be I J inches square and long enough to set the wheels 10 inches between the flanges ; the boxes to be 1 inches thick, and all made of the best wrought iron. Piping:, etc. All piping, hose, valves, bibs, cocks, ells, tees, unions, etc,, to be furnished as per detailed bill. All necessary bolts, belts, nuts, and washers, also copper plate for battery and aprons, to be furnished of proper weight, and as shown on drawings, 1 inch thick, not plated; also, silver-plated copper plate, 20 inches wide and 20 feet long. Belting-. One (i) main driving belt, to be about 55 feet long, 20 inches wide, and made of the best 5 ply rubber of the "Boston Belting and Packing Co.'s" manufacture, patent stretched. Battery Belts. One hundred and ninety (190) feet of the best 5 ply rubber, 16 inches wide. Rock Breaker Belt. Ninety (90) feet of 4 ply rubber, 12 inches wide.

Continue on to:

Evolution Of Mining Methods In The North, Part I

Return To:

Hard Rock Quartz Mining and Milling